CNC Turning

Precision turned parts from Ø3 to Ø300 mm — one-off parts, small batches and unmanned 24/7 production. ISO 9001-certified quality processes.

What is CNC Turning?

In CNC turning, the workpiece rotates at high speed while a cutting tool removes material. This produces rotationally symmetric parts such as shafts, bushings, bolts and thread adapters.

With live tooling and Y-axis we also machine pockets, hex contours, flats and cross-bores directly on the lathe — no need to re-clamp on a mill.

Our Turning Centers

DMG Mori NLX 2000|SY

Our powerful turning center for medium to large workpieces. With Y-axis and sub-spindle for complete machining.

Traub TNL 32

Swiss-type lathe for small to medium diameters. With bar feeder for unmanned 24/7 series production.

24/7 Unmanned

With our bar feeder, we produce series around the clock without an operator. The bar is fed automatically, parts are parted off and the next workpiece starts immediately.

The result: Cost-effective series production with consistent quality and short lead times, even for larger quantities.

From Ø3 to Ø300

With two specialized machines, we cover the complete diameter spectrum. Small precision parts on the Traub, large shafts and flanges on the NLX.

Complete Machining

With live tooling and Y-axis we machine hex contours, flats, pockets and cross-bores directly on the lathe, without re-clamping on a mill. This saves setup time, eliminates positioning errors and makes us significantly more efficient.

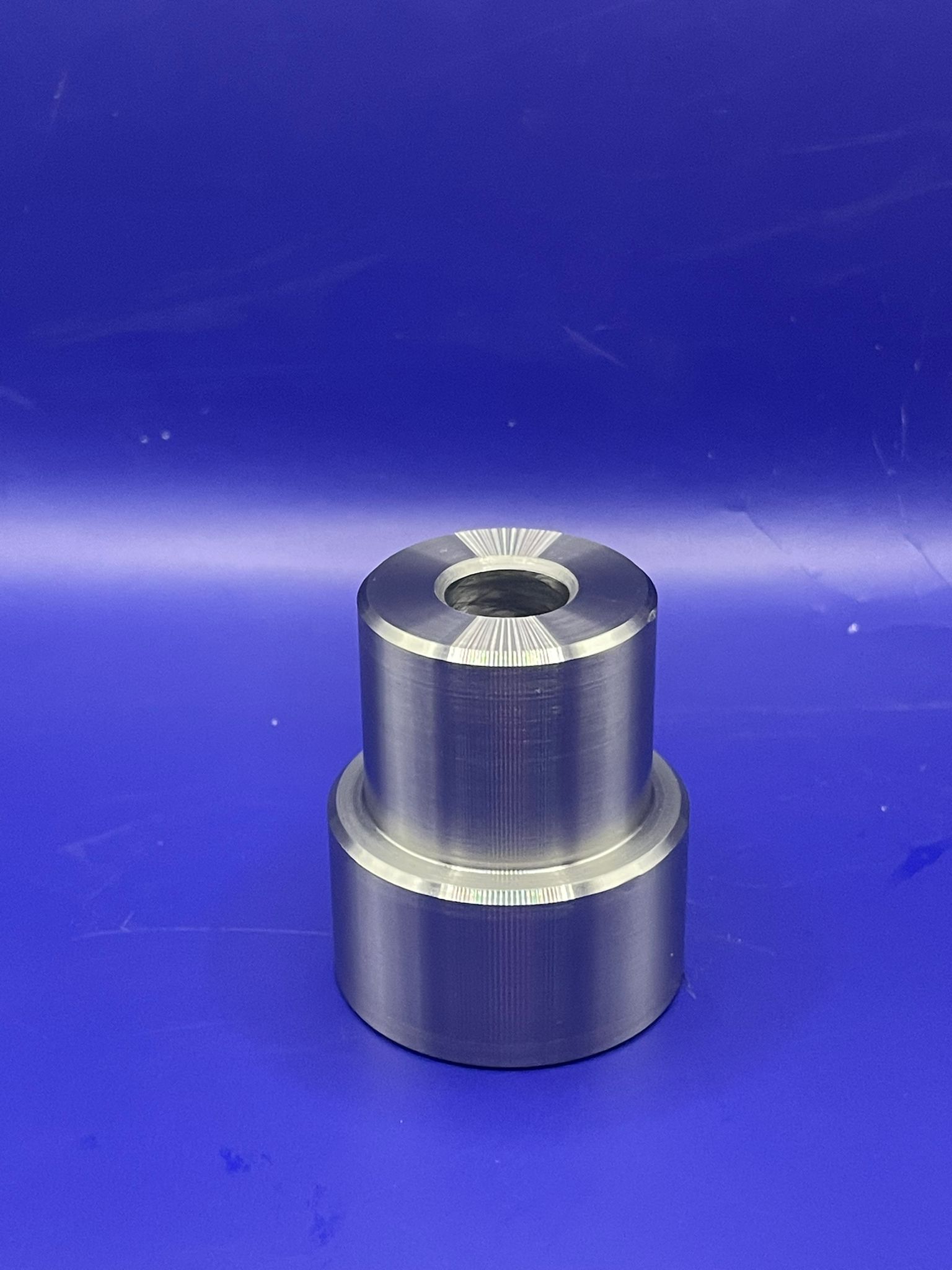

Typical Turned Parts

Shafts & Stepped Bolts

Stepped shafts, stepped axles and keyway connections in all common steels and alloys.

Threaded Parts

Thread adapters, screws, bolts — metric, fine thread and custom threads to drawing.

Bushings & Sleeves

Bearing bushings, spacer sleeves and precision fits — precise internal machining with tight tolerances.

CNC Turning in Action

Request a Turned Part

Send us your drawing — we'll calculate your turned part and deliver reliably.

Start a Request