CNC Blog

Expert knowledge, trends and insights from the world of CNC manufacturing.

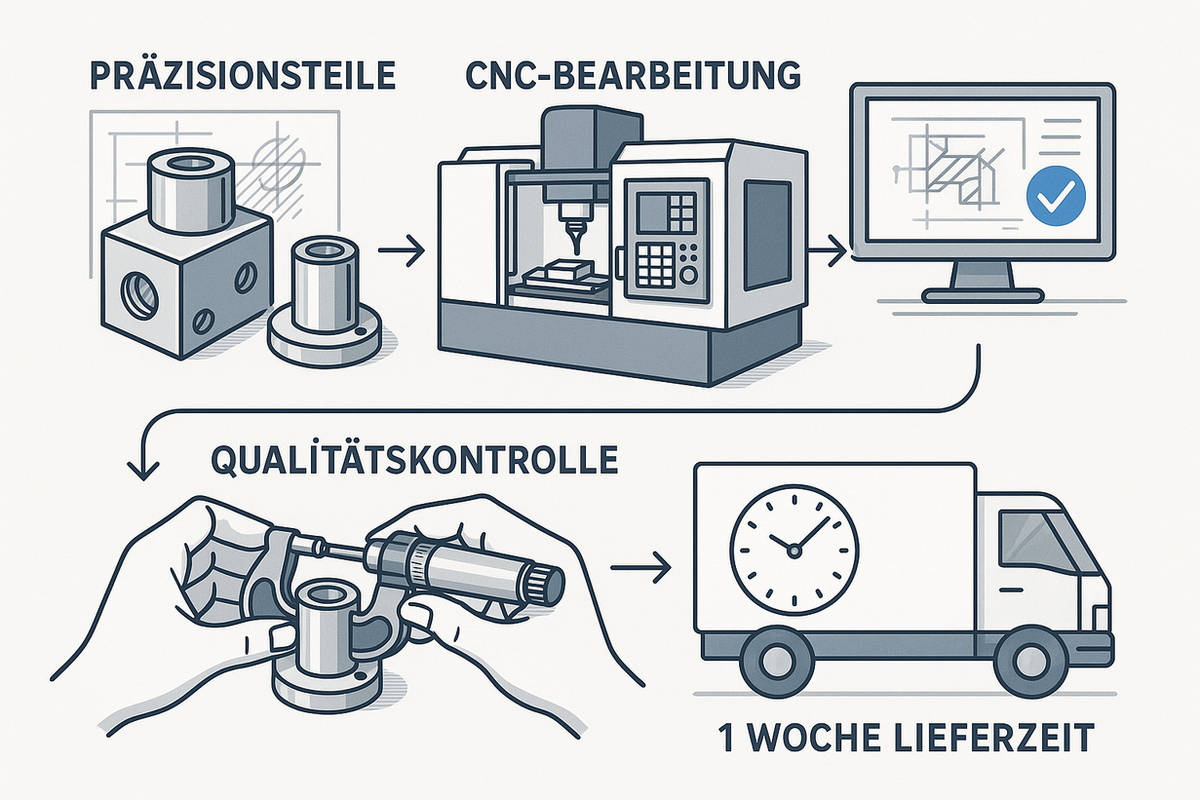

CNC One-Off Parts in 1 Week: How Fast Programming Saves Costs

Learn how fast CNC programming reduces lead times for one-off parts to just one week while simultaneously cutting costs.

Who Is the Right Partner for Precision Parts Manufacturing?

Precision parts manufacturing: What matters when choosing a partner — speed, process reliability and quality. Find out now.

Who Is the Right Partner for Small Batch Production?

Small batches require a flexible CNC partner. Learn what matters for quantities of 5 to 500 pieces.

CNC One-Off Parts in 1 Week: How Fast Programming Saves Costs

Learn how fast CNC programming reduces lead times for one-off parts to just one week while simultaneously cutting costs.

Who Is the Right Partner for Precision Parts Manufacturing?

Precision parts manufacturing: What matters when choosing a partner — speed, process reliability and quality. Find out now.

Who Is the Right Partner for Small Batch Production?

Small batches require a flexible CNC partner. Learn what matters for quantities of 5 to 500 pieces.

Who Is the Right Metalworking Service Provider for Your Project?

Choosing the right metalworking service provider determines the quality, reliability and costs of your project. What to look for.

CNC Contract Manufacturing Metal: One-Off Parts and Series from Specialists

CNC contract manufacturing for metal parts — from one-off pieces to series. Learn how a specialised partner ensures quality and efficiency.

Vibrations and Surface Quality: How to Avoid Chatter Marks

Vibrations are the most common cause of poor surfaces. Learn how to recognise and systematically avoid chatter marks in CNC milling.

Aluminium Alloys Compared: Which Is Best for CNC Machining?

Not all aluminium is the same. Learn which alloys are suitable for CNC machining — and why the choice is critical.

Impact of Tool Materials and Coatings on Precision Machining

The choice of tool material and coating has an enormous impact on machining performance and tool life.

Coolants in Machining: Impact on Quality and Tool Life

Coolants affect surface quality, tool life and process reliability. An overview of types, applications and current trends.

CNC Turning vs. CNC Milling: When to Use Which Process?

CNC turning and CNC milling are the two most important machining processes. Learn when which process is the better choice.

Cost Factors in Machining: What Determines Your Unit Price?

Material, machining time, setup — learn which factors actually determine the costs when CNC machining.

CNC Machining: A Guide for Buyers and Engineers

Buying CNC parts? This guide shows you what to consider to get the best quality at a fair price.

Factors Influencing CNC Precision: What Really Matters

CNC precision depends on many factors. From machine quality to climate control — learn what really makes the difference.

Drawn vs. Extruded Bar Stock: The Crucial Difference for CNC Parts

Drawn or extruded? The choice of bar stock directly affects accuracy, surface quality and manufacturing costs.

Semi-Finished Products in Metalworking: Which Stock Shape for Your Part?

Round bar, flat bar, plate or tube — the choice of starting stock shape directly affects CNC manufacturing costs.

Innovative Applications of CNC Machining in Modern Industry

Innovative CNC machining: From medical technology to aerospace to motorsport — discover modern applications of precision manufacturing.

Sustainable Metalworking: Resource Conservation in CNC Manufacturing

Sustainable metalworking: chip recycling, coolant management and energy efficiency — how CNC shops reduce costs and conserve resources.

Quality in Metal Manufacturing: What Makes a Good Supplier

Quality in metal manufacturing goes beyond dimensional accuracy. Learn what factors distinguish a reliable supplier.

The Importance of Precision in Metalworking

Precision in metalworking: dimensional accuracy, form accuracy and surface quality — how top results are achieved. Read now.

From Raw Material to Masterpiece: The Journey of a CNC Component

CNC manufacturing step by step: from raw material to precision part — material selection, programming, machining and quality inspection.

Common Welding Defects and How to Avoid Them

Avoiding welding defects: porosity, cracks, lack of fusion and distortion — recognise causes and prevent with proven strategies. Read now.