CNC Milling

From simple contours to complex 3D geometries — precision milling on up to 5 axes.

What is CNC Milling?

In CNC milling, a high-speed rotating tool precisely removes material from the workpiece. Computer-controlled axis movements create precise contours, pockets, bores and freeform surfaces.

Unlike turning, here the tool moves, not the workpiece. This enables machining of components with virtually any geometry — prismatic, round or freeform.

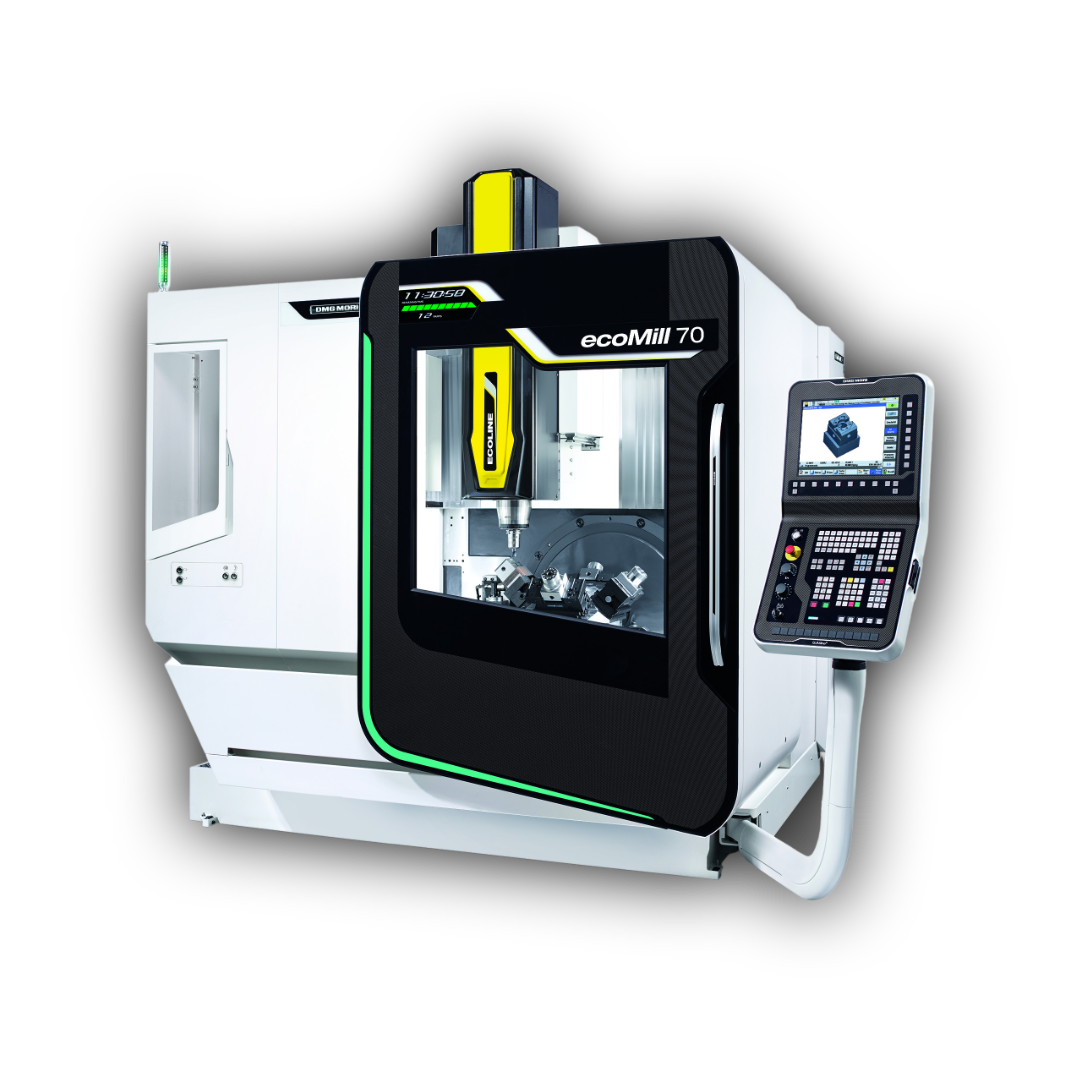

DMG Mori

Ecomill 70

Our 5-axis machining center for demanding workpieces. Direct drives and thermal stabilization ensure consistent precision, even during long run times.

Materials & Workpieces

We machine a broad spectrum of materials, from structural steel to high-strength alloys, titanium and engineering plastics.

Tolerances & Surface Finish

Our milling achieves tolerance class IT6 per DIN ISO 286. Every part is measured and documented within our ISO 9001-certified quality management system, with full measurement reports available on request.

Typical Milled Parts

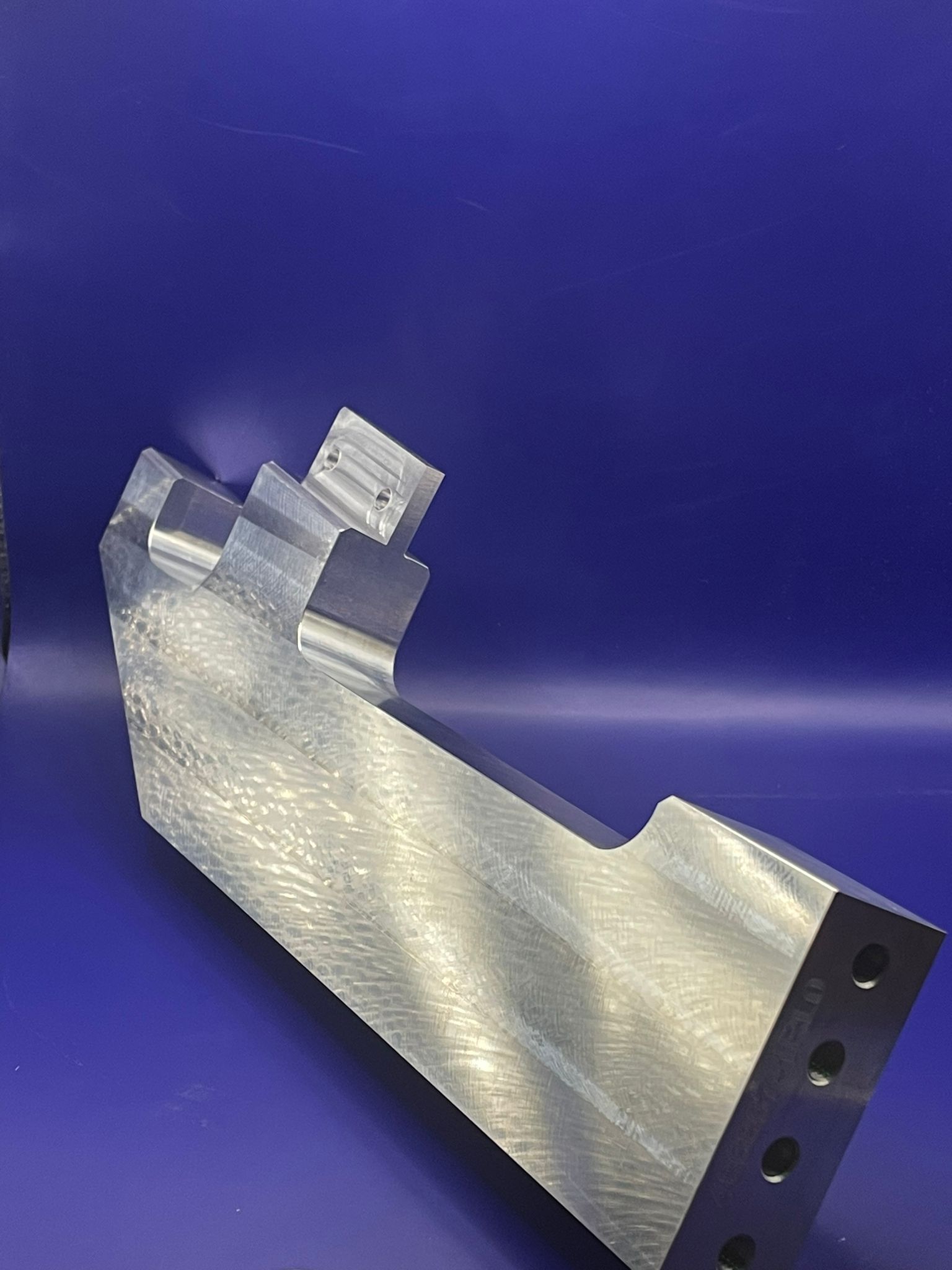

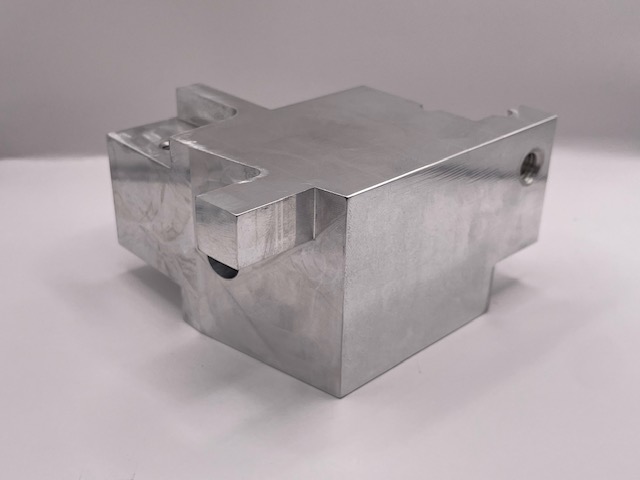

Brackets & Housings

Complex aluminum milled parts with contours, pockets and bores for mechanical engineering and fixtures.

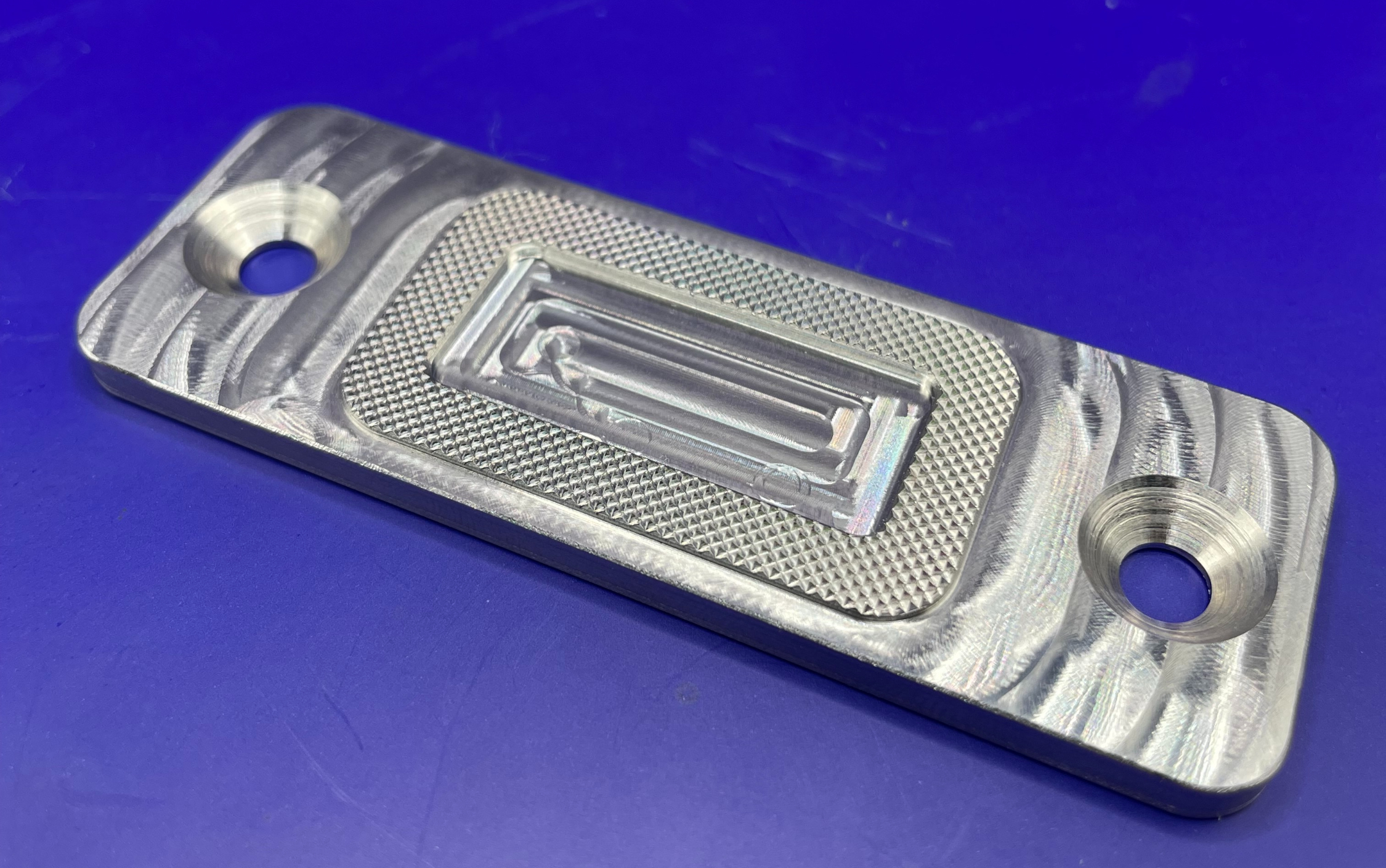

Stamps & Tooling

Precision-milled stamps and tool inserts with knurling, engraving and fine contours.

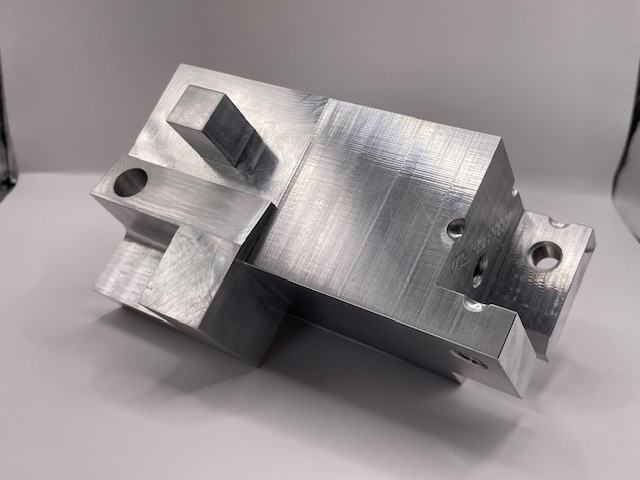

Aluminum Components

Lightweight, dimensionally accurate parts from aluminum, ideal for series production and prototypes.

CNC Milling in Action

Request a Project

Send us your drawing or 3D model — we'll provide a no-obligation quote.

Start a Request