PrecisionMachining

CNC Contract Manufacturing from Northern Germany

We provide precise and reliable contract manufacturing in metalworking. With state-of-the-art CNC machines and premium tooling, we produce parts to your exact specifications — from prototypes to high-volume production.

Parts

Clients

Production

Tolerance Class

Satisfied Clients

Automated Production

Certified

Precision to

IT6 Level

Two disciplines, one philosophy: Every µm counts. Our manufacturing process starts where others stop.

Precision in

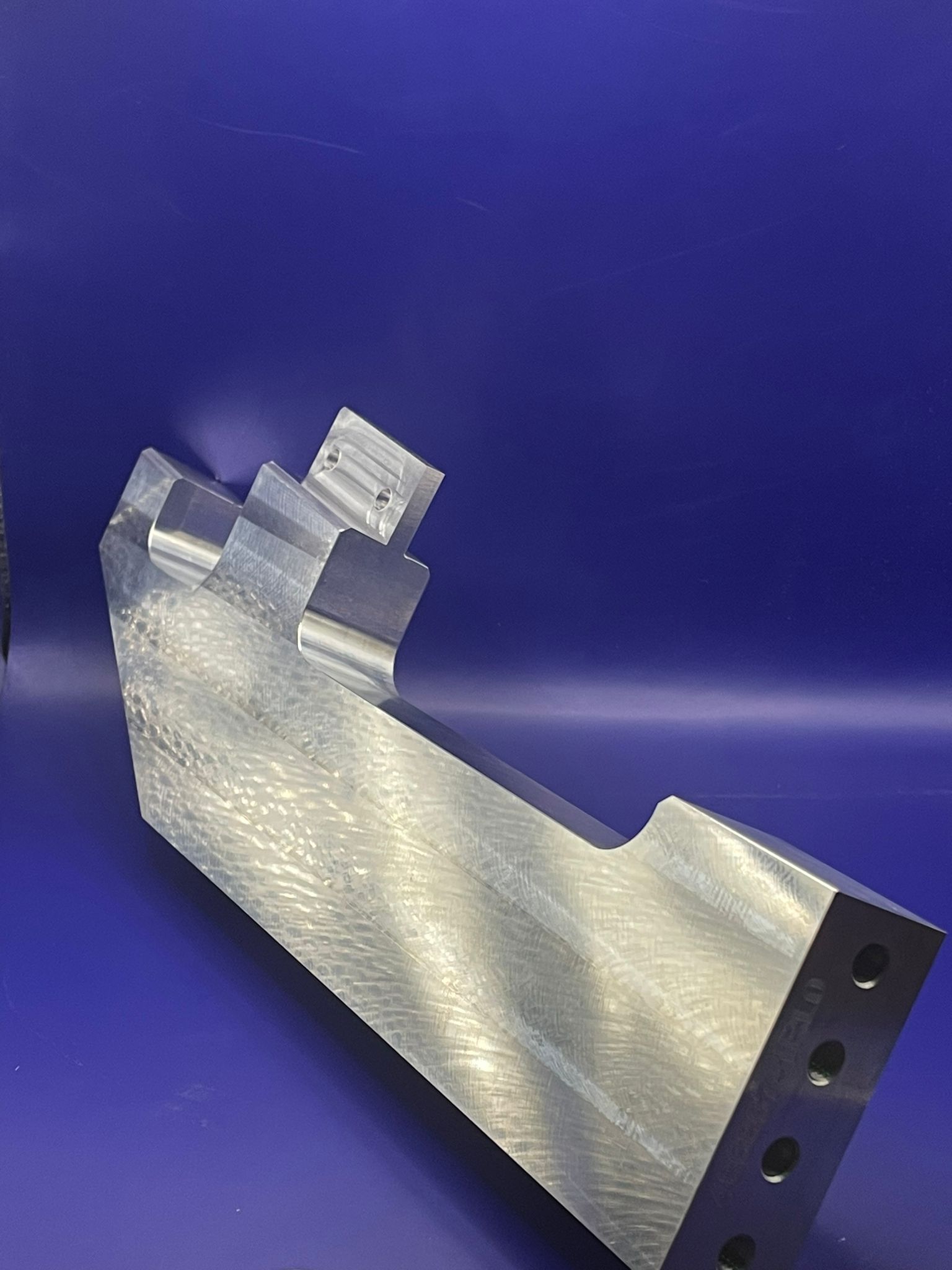

Every Contour

In CNC milling, material is precisely removed layer by layer to create the finished workpiece from a blank. From simple contours to complex 3D shapes, we machine on our DMG Mori Ecomill 70 with up to 5 axes.

Precision

Turned Parts

From one-off manufacturing to lights-out 24/7 series production. Our DMG Mori NLX 2000|SY and Traub TNL 32 cover the full turning spectrum , with sub-spindle and live tooling.

Powered by

TopSolid

Integrated CAD/CAM with Digital Twins of our machines — for maximum efficiency, precision and full documentation.

Digital Twin

Technology

Our CNC machines exist as complete digital twins in TopSolid. Every tool, every position, every machining step — precisely mapped and simulated before chips fly.

- Full machine simulation before production

- Documented tool usage (position & parameters)

- Complete traceability of every machining step

Fast & Precise

Programming

With TopSolid's integrated CAD/CAM solution, we program complex parts efficiently and error-free. From 3D drawing directly to optimized NC code — fully digital.

- Direct CAD-to-CAM transfer without data loss

- Collision checking and simulation before production

- Complex 5-axis parts safely programmed

Trust through

Transparency

We know what matters to procurement: Certification, traceability, data security, and a partner who thinks ahead.

ISO 9001 Certified

Our QMS is ISO 9001 certified. Every process is documented, audited and continuously optimized.

Inspection Reports & Certificates

EMPB reports, dimensional protocols, material certificates 3.1 — complete documentation for every batch.

Traceability

Every part is fully traceable through our proprietary ERP system, from raw material to delivery.

Data Protection & NDA

GDPR compliant, encrypted communication, non-disclosure agreements — your data and drawings are secure.

ERP Integration

Our proprietary ERP system enables digital interfaces (API/EDI) for seamless integration into your supply chain.

On-Time Delivery & Tracking

On-schedule delivery with real-time status tracking. Full transparency from order entry to dispatch.

Cross-Industry

Capabilities

From medical technology to electrical engineering, we understand the requirements of your industry and manufacture accordingly.

Mechanical Engineering

Precision parts for special-purpose and production machines, from individual components to assembly-ready sub-assemblies.

Medical Technology

Biocompatible materials, tight tolerances and full traceability for medical devices and implants.

Automotive

Prototypes and production parts for automotive suppliers, short lead times, reproducible quality.

Aerospace

Highest requirements for material and documentation — titanium, Inconel and high-strength aluminum alloys.

Energy & Environment

Components for renewable energy, wind power and industrial systems from corrosion-resistant materials.

Electrical Engineering

Housings, heat sinks and precision parts for electronic assemblies, control cabinets and automation systems.

Reference

Portfolio

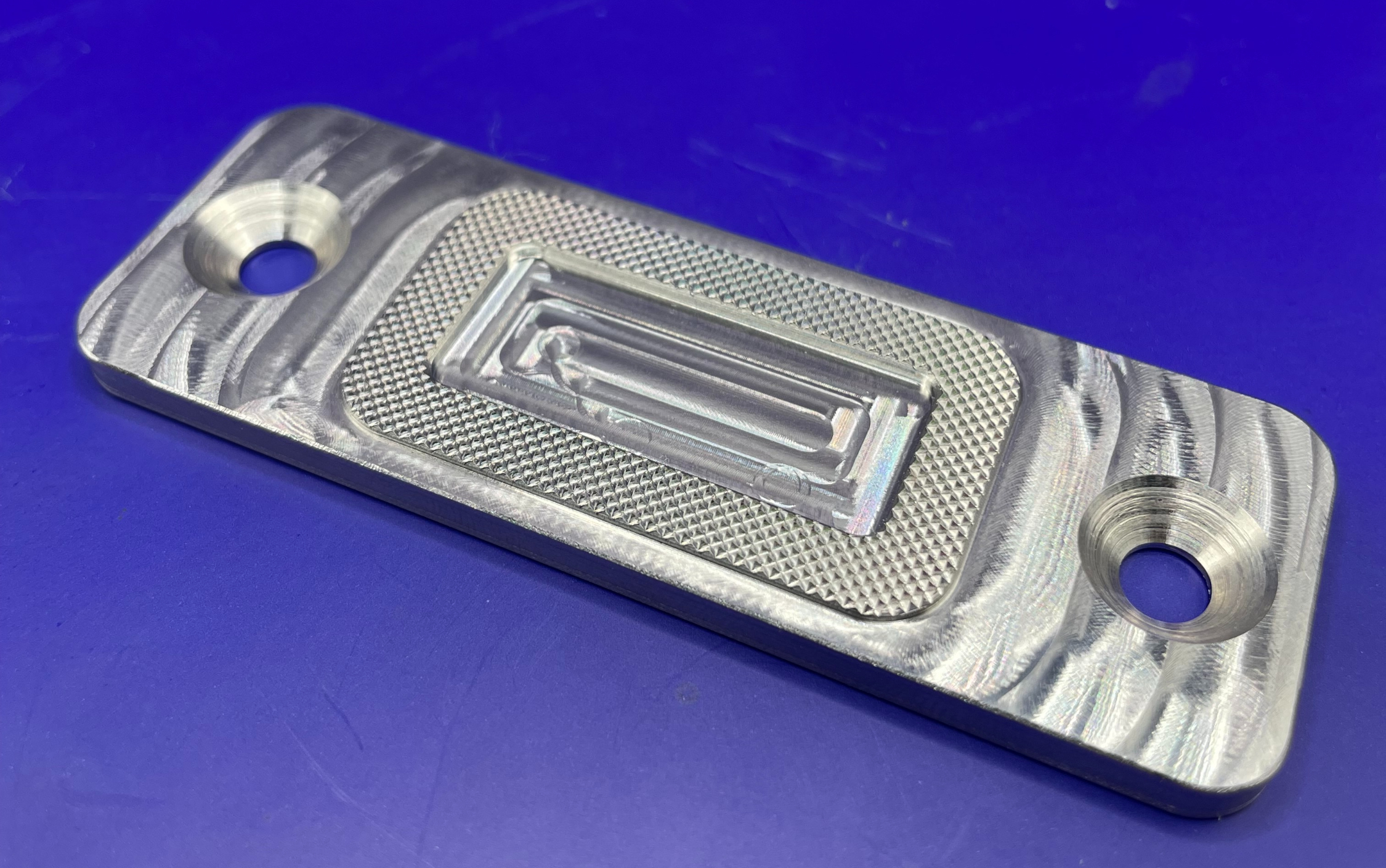

Industrial Components

High-precision milled parts for industrial applications.

Series Production

Efficient production of turned parts in medium and high volumes.

Prototypes

Fast realization of complex one-off parts from drawings.

Ready for the

next step?

Let's discuss your next project together. We offer no-obligation consultations on feasibility and cost.