Precision Parts — Tolerances from IT6

Precision turned and milled parts with tolerances from IT6, H7 fits and surfaces down to Ra 0.4. Including knurling and 100% measurement protocol.

Precision at the Highest Level

Precision parts with tolerances below ±0.01 mm require stable machines, temperature-controlled production and experienced operators. Every fit, every surface and every thread tolerance must be perfect — on the first part just as on the thousandth.

On our DMG Mori NLX 2000 (turning) and Ecomill 70 (milling) we manufacture precision parts with IT6 tolerances, H7 fits and surfaces down to Ra 0.4. Knurling, fine turning and hard machining are part of our standard capabilities.

Materials for Precision Parts

Precision is material-independent — we manufacture your parts from the optimal material with IT6 accuracy.

Aluminium (EN AW-6082/7075)

Lightweight and excellent machinability. Surfaces down to Ra 0.4 by fine turning. Ideal for optics, metrology and lightweight construction.

Stainless Steel (1.4301/1.4404)

Corrosion resistant with tightest tolerances. H7 fits in stainless steel require sharp tools and stable clamping.

Free-Cutting Steel (11SMnPb30)

Best machinability for highest volumes. Surfaces Ra 0.8 directly from the machine.

Quenched & Tempered Steel (42CrMo4)

High strength with good toughness. Precision shafts and bolts with H6 fits.

Brass (CuZn39Pb3)

Decorative and excellent machinability. Smooth surfaces and tight tolerances for fittings and contacts.

Titanium (Grade 5)

Highest strength at lowest weight. Precision parts for medical technology and aerospace with IT7 tolerances.

Benefits for Precision Parts

Tolerances from IT6

Dimensional tolerances ±0.008 mm — reproducible across the entire batch. Documented with 100% measurement protocol.

H7/g6 Fits

Clearance fits and transition fits according to ISO 286. Bores and shafts with precise tolerance fields.

Surfaces Ra 0.4

By fine turning, grinding or polishing. Mirror-smooth surfaces for sealing faces, bearings and optical components.

Knurling per DIN 82

Cross and straight knurling RGE 0.5 to 1.6 — directly on the lathe. For grip and aesthetics.

100% Measurement Protocol

Every dimension is inspected and documented. On request with First Article Inspection Report (FAIR) per VDA.

Small Series & Single Parts

Precision from batch size 1. Economical through optimized setup times and CAM programming.

Your Precision Part in 5 Steps

Send Inquiry

Send drawing or 3D model with tolerances, fits and surface requirements.

Review & Quote

Feasibility check of tolerances. Consultation on clamping and measurement concept. Quote in 24h.

Approval

After approval we create the CNC program and procure raw material.

Precision Manufacturing

CNC turning on NLX 2000 and/or 5-axis milling on Ecomill 70. 100% inspection.

Delivery

Quality inspected, with measurement protocol, carefully packaged and shipped.

Our Accuracy

Dimensional Tolerances from IT6

±0.008 mm for diameters up to 50 mm. IT7 for larger dimensions. Reproducible across the entire series.

Fits H7/g6/h6

Clearance fits H7/g6, transition fits H7/k6 and press fits H7/p6 according to ISO 286-1.

Surfaces down to Ra 0.4

Ra 0.8 as standard through fine machining. Ra 0.4 by fine turning. Ra 0.2 by polishing on request.

Geometric Tolerances

Runout ≤ 0.01 mm, flatness ≤ 0.005 mm, coaxiality ≤ 0.015 mm — measured and documented.

Machines for Precision Parts

DMG Mori NLX 2000

CNC lathe with live tooling for precision turned parts.

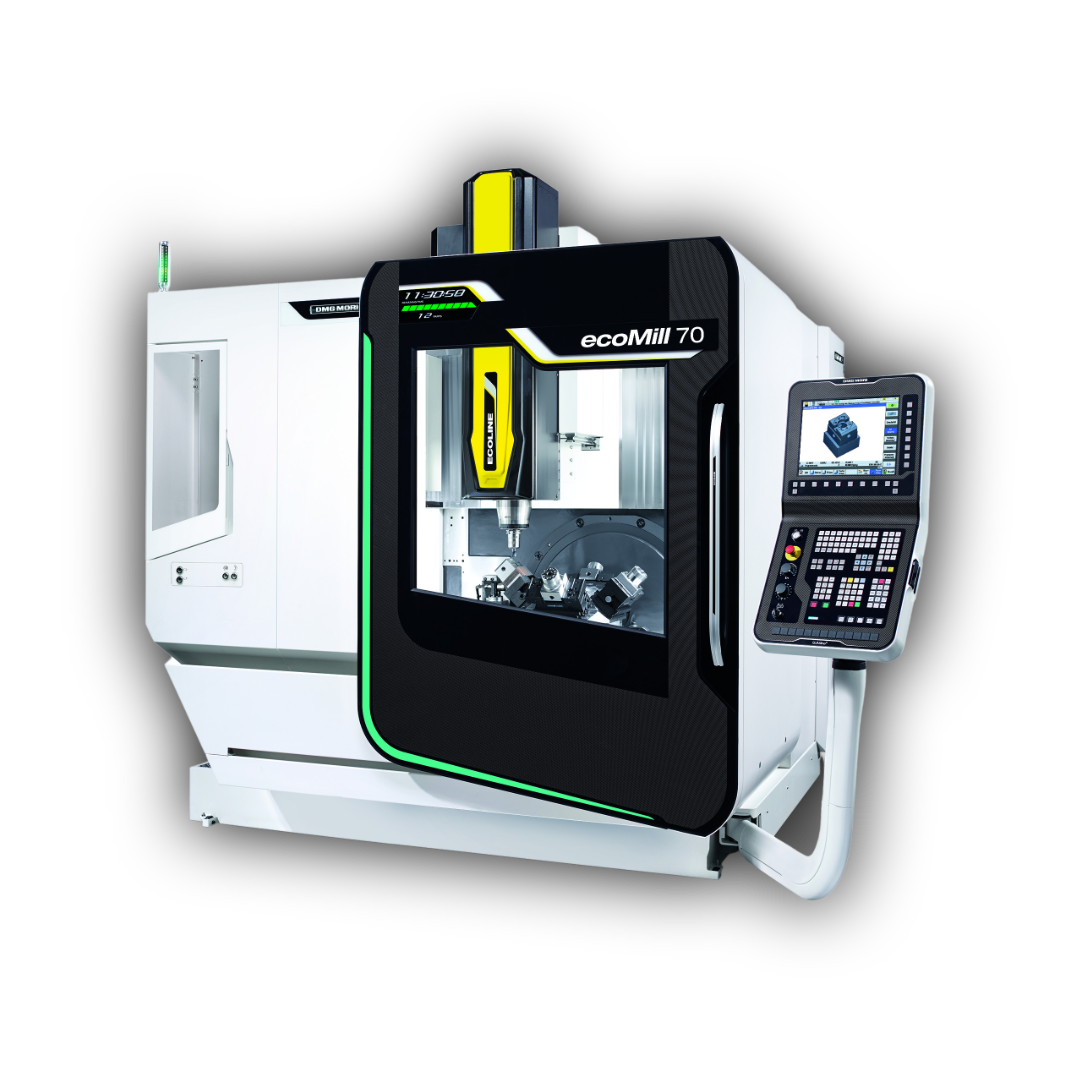

DMG Mori Ecomill 70

5-axis machining center for precision milled parts with complex geometries.

Precision Parts for Your Industry

Metrology

Fixtures, adapters and test specimens with IT6 tolerances and Ra 0.4 surfaces.

Medical Technology

Implants and instruments from titanium and stainless steel with H7 fits and knurling.

Optics & Fine Mechanics

Lens mounts and adjustment elements from aluminium with Ra 0.2 surfaces.

Mechanical Engineering

Dowel pins, guide shafts and bearing seats with h6 fits and runout ≤ 0.01 mm.

Hydraulics & Pneumatics

Pistons, valve bodies and sealing seats with tightest fits for leak-free operation.

Automation

Spindles, grippers and positioning elements with highest dimensional accuracy.

Questions about Precision Parts

Q1What tolerance class do you manufacture?

Standard IT7, IT6 (±0.008 mm) on request. For particularly tight tolerances IT5 in individual cases after consultation.

Q2What does a precision part cost?

Simple precision turned parts from approx. €15–30/piece (IT7, Al). IT6 parts with H7 fit and measurement protocol from approx. €40–80/piece depending on material and geometry.

Q3Can you produce knurling?

Yes — cross knurling (RGE) and straight knurling (RAA) per DIN 82 in pitches 0.5 to 1.6 mm. Directly on the NLX 2000.

Q4Do we receive a measurement protocol?

Yes — every precision part is 100% measured. On request we create a First Article Inspection Report (FAIR) per VDA or PPAP per AIAG.

Q5Which fits do you manufacture?

All common ISO fits: H7/g6 (clearance fit), H7/k6 (transition fit), H7/p6 (press fit). For bores and shafts.

Q6What surfaces do you achieve?

Standard Ra 1.6, fine machining Ra 0.8, fine turning Ra 0.4. Ra 0.2 possible by polishing. Per DIN EN ISO 4287.

Q7From what quantity is precision worthwhile?

From 1 piece — we manufacture precision parts as single parts or prototypes too. Setup costs for IT6 production are only slightly higher than standard.

Q8Can you also hard turn?

Yes — hardened materials up to 62 HRC are machined by hard turning on the NLX 2000. Alternatively we arrange grinding through our partner network.

Request Precision Part

Send us your drawing with tolerance specifications — we deliver a binding quote within 24 hours.