Custom Parts & Flanges to Drawing

Individual flanges, adapters and special components from CNC manufacturing. DIN-compliant or to your drawing — from lot size 1.

From One-Off to Series

Custom parts, flanges and adapters are the backbone of every special-purpose machine. We manufacture to drawing, STEP or 3D model — in the tolerance class your application requires.

Whether connection flange for hydraulics, adapter between two standards or an entirely new component: Our 3- and 5-axis milling machines and CNC lathes cover the full spectrum.

Flanges, Adapters & Custom Parts

From standard shapes to highly complex one-offs — we manufacture what you need.

Connection Flanges

DIN, ANSI or custom flanges with bolt patterns to drawing. All common materials.

Hydraulic Adapters

Transition pieces between different thread sizes and standards. Leak-proof and pressure-rated.

Spacers

Spacer blocks, intermediate rings and distance plates. Exact lengths and parallelism.

Brackets

Sensor holders, motor consoles and pivot bearings. 3D contours machined from solid.

Coupling Pieces

Connecting elements between shafts, motors and gearboxes. Tight fits and zero backlash.

Custom Housings

Protective housings, valve blocks and manifolds. Multi-side machining in one setup.

Why Strobel for Custom Parts

From 1 Piece

No minimum order, no tooling costs. Even one-offs and prototypes are carefully manufactured.

All Materials

Steel, stainless steel, aluminium, brass, copper, titanium, plastic — we machine what your application demands.

Complete Machining

Turning and milling in one setup. Fewer setups = more precision.

CAD Support

We read STEP, IGES, DXF and PDF drawings. We clarify technical questions when needed.

Express Possible

Rush manufacturing in 3–5 working days. We prioritize your part when it's urgent.

Documentation

Dimensional reports, material certificates (3.1) and declarations of conformity on request.

In 5 Steps to Your Part

Send Drawing

By email or inquiry form. STEP, DXF, PDF — all formats welcome.

Quote in 24h

We calculate unit price, lead time and any tooling costs. Transparent and binding.

Approval

You approve the order. For series parts, optionally with first article inspection.

Manufacturing

CNC turning and milling on state-of-the-art machines. 100% inspection.

Delivery

Safely packaged with dimensional report. Express shipping for rush orders.

Manufacturing Precision

General Tolerances

DIN ISO 2768-m/f as standard. Tighter tolerances per drawing entry, down to IT6.

Surface Finish

Ra 1.6 as standard, Ra 0.4 or better for ground surfaces and fits.

Position Accuracy

Bolt patterns and hole patterns with ±0.02 mm position. Exact pitch circle diameters.

Parallelism

≤ 0.01 mm for sealing and mounting surfaces. Guaranteed leak-free connections.

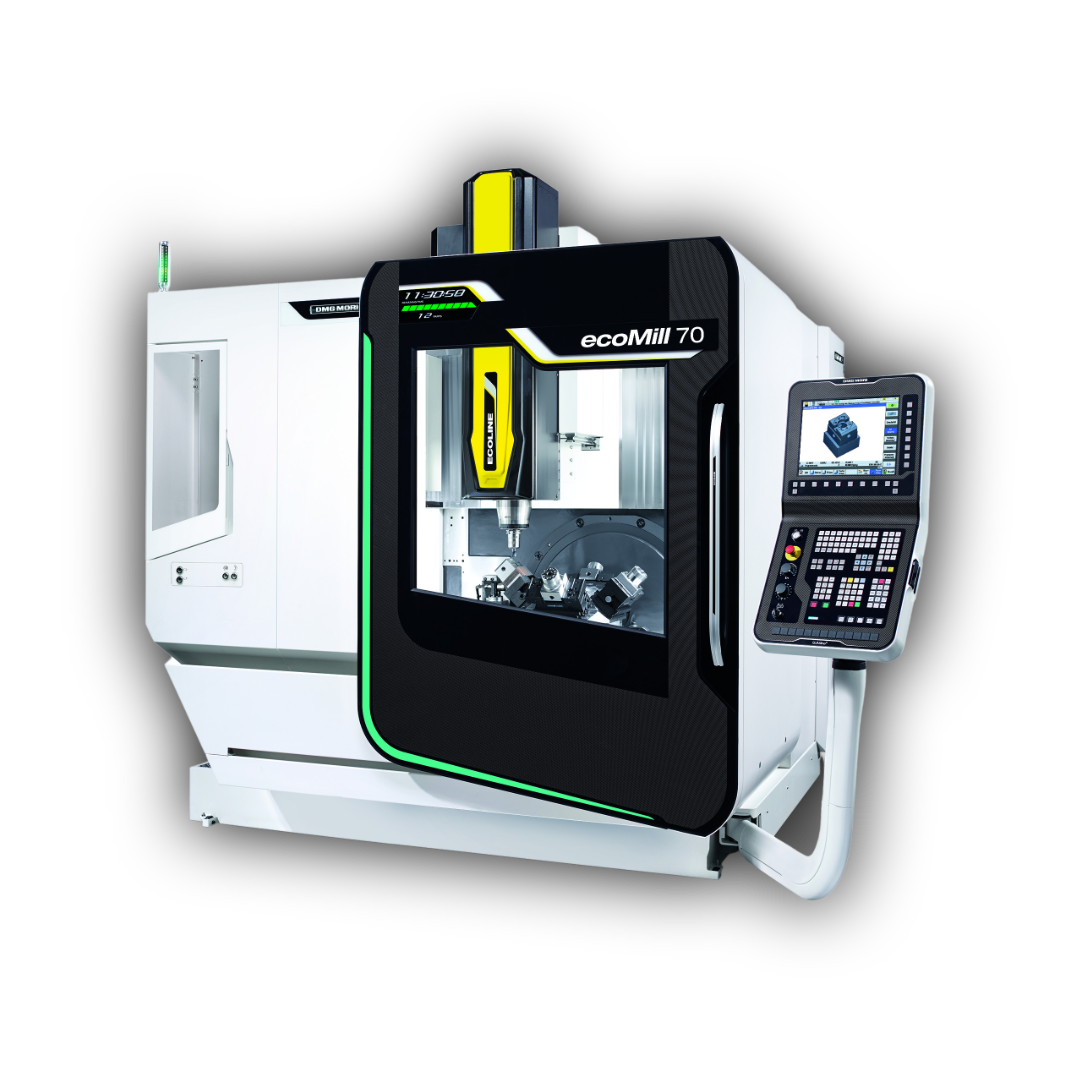

Our Machines

DMG MORI Ecomill 70

3-axis milling center with large travel — ideal for flanges and plates.

DMG MORI NLX 2000

CNC lathe with driven tools for adapters and coupling pieces.

Custom Parts for Your Industry

Mechanical Engineering

Flanges, consoles and custom parts for plants and special-purpose machines.

Hydraulics

Adapter pieces, manifolds and connection plates for hydraulic systems.

Medical Technology

Stainless steel custom parts with high surface quality for medical devices.

Automotive

Test fixtures, tool holders and measuring device holders.

Shipbuilding

Corrosion-resistant flanges and adapters for maritime applications.

Energy Technology

Flanges and transition pieces for wind, solar and conventional power plants.

Frequently Asked Questions

Q1What are custom parts?

Custom parts are components not available off the shelf, manufactured to your individual drawing or 3D model.

Q2What types of flanges can you produce?

We produce DIN flanges, ANSI flanges, custom flanges and plate flanges. Also with individual bolt patterns and sealing faces.

Q3Which materials do you work with?

Steel (S355, C45), stainless steel (304, 316), aluminium (6082, 7075), brass, copper, titanium and plastics like POM, PEEK.

Q4Is there a minimum order quantity?

No. We manufacture from 1 piece. Especially for custom parts, one-off production is our core competence.

Q5How fast can a custom part be produced?

Standard lead time 5–8 working days. Rush manufacturing in 3–5 days is possible, faster by arrangement.

Q6Can you also assemble assemblies?

Yes, we also handle assembly of multi-part assemblies on request.

Q7Which file formats do you accept?

STEP, IGES, DXF, DWG and PDF drawings. When in doubt, send us what you have — we'll find a solution.

Q8Do you offer surface treatment?

Yes, we coordinate anodizing, blackening, nickel plating, chromating and other coatings through our partners.

Custom Part Request

Send us your drawing — we'll quote within 24 hours. From 1 piece, any material.