Milled Parts from Titanium, Copper, Plastics & Brass

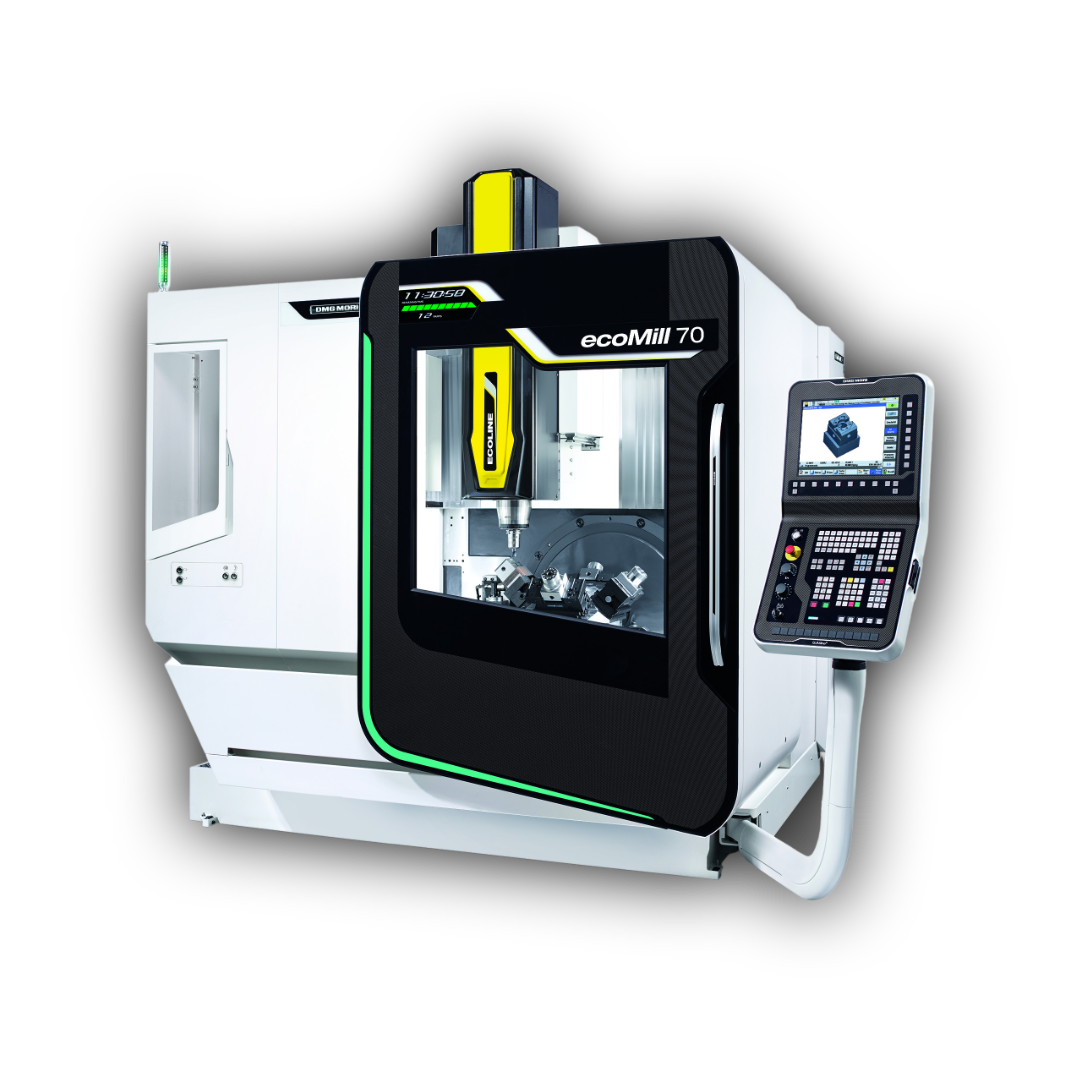

CNC milled parts from titanium, copper, bronze, PEEK, POM and brass. 5-axis machining on DMG Mori Ecomill 70 — including thread machining. Quote in 24h.

CNC Milling Titanium, Copper & More

Titanium, copper and engineering plastics each require completely different machining strategies: Low cutting speeds for titanium, sharp tools for sticky copper alloys and specialized plastic cutters for PEEK and POM. We also routinely machine non-ferrous metals like brass.

On our DMG Mori Ecomill 70 (travel 700 × 560 × 510 mm) we machine all these materials in 5 axes. Thread machining, precision bores and freeform surfaces are created in a single setup — saving re-clamping time and increasing accuracy.

Materials for Milled Parts

From titanium to copper to PEEK — we mill the optimal material for your application. Material consultation included.

Ti Grade 5 (Ti6Al4V)

Highest strength at lowest weight. For aerospace, medical technology and highly stressed lightweight components.

E-Cu57 (Electrolytic Copper)

Highest electrical conductivity. For busbars, contacts, heat sinks and electrodes in semiconductor technology.

PEEK (Polyetheretherketone)

High-temperature plastic (up to 260°C) with excellent chemical resistance. For seals, insulators and implants.

POM (Polyoxymethylene)

High stiffness, low friction, good dimensional stability. For gears, guides and precision parts in mechanical engineering.

CuSn8 (Bronze)

Excellent sliding properties and high wear resistance. For plain bearings, worm gears and guide bushings.

CuZn39Pb3 (Brass)

Good machinability, corrosion resistant, decorative. For valve bodies, fittings, plain bearings and decorative components.

Benefits for These Materials

Material Expertise

Titanium, copper, bronze, plastics and brass — each material requires specific cutting data. We master them all.

Thread Machining

Metric threads, fine pitch and imperial threads directly in the clamping. Helicoil pilot holes for soft materials.

5-Axis Machining

Complex geometries in a single setup. Undercuts and angled bores without re-clamping.

Small Series & Single Parts

Economical from 1 piece. We procure special materials at short notice through our network.

All Formats

STEP, DXF, PDF — CAM programming directly from your 3D model. Also sketches as a starting point.

Post-Processing

Polishing, anodizing (titanium), gold plating (brass), nickel plating (copper) — through certified partners.

Your Special Material Part in 5 Steps

Send Inquiry

Send drawing or 3D model with material, quantity and delivery date. Material consultation included.

Review & Quote

Feasibility check, material procurement and clamping concept. Binding quote within 24h.

Approval

After approval we procure raw material — plates, round bars or profiles in the desired material.

CNC Milling

5-axis machining on DMG Mori Ecomill 70. Material-specific cutting data and 100% inspection.

Delivery

Quality inspected, deburred, with surface treatment if needed. Carefully packaged and shipped.

Precision for Special Materials

Dimensional Tolerances from IT7

Even for difficult-to-machine materials like titanium. For brass and plastics, IT6 fits are also possible.

Surfaces to Ra 0.8

Brass and bronze can be mirror-polished (Ra 0.2). Titanium and copper typically Ra 0.8–1.6.

Threads IT6H

Metric, fine pitch, imperial — form-cut threads in brass and plastic. Thread milling for titanium and hardened parts.

Thermal Expansion

Plastics have 5–10× higher thermal expansion than metal. We compensate through climate-controlled manufacturing and adjusted allowances.

Our Milling Machine for Special Materials

DMG Mori Ecomill 70

5-axis machining center with large work envelope. Stable enough for titanium, sensitive enough for plastics.

Special Material Milled Parts for Your Industry

Mechanical Engineering

Bronze plain bearings, POM guides, brass valve bodies — special materials for special applications.

Medical Technology

PEEK implants and titanium instruments. Biocompatible, sterilizable and manufactured to drawing.

Electrical Engineering

Copper busbars, brass contacts and PEEK insulators. Highest conductivity and insulation values.

Aerospace

Titanium structural parts with highest strength at lowest weight. 5-axis geometries to aerospace standards.

Food Technology

Brass and bronze components for fittings and pumps. FDA-compliant plastic parts from PEEK.

Optics & Precision

Brass mounts and copper heat sinks for optical instruments. Highest surface quality.

Questions about Milled Parts from Special Materials

Q1Which special materials can you mill?

Brass (CuZn39Pb3, CuZn37), titanium (Grade 2, Grade 5), copper (E-Cu57, E-Cu58), bronze (CuSn8, CuAl10), PEEK, POM, PA6.6 and other engineering plastics. Also exotic alloys on request.

Q2Is titanium difficult to mill?

Yes — titanium requires low cutting speeds, high feed rates and stable clamping. Our Ecomill 70 is designed for this. Tool costs are higher, which is reflected in the unit price.

Q3Can you mill threads in brass?

Yes — metric threads M2 to M24, fine pitch and imperial threads directly in the clamping. For brass we use form-cut threads for optimal surface quality.

Q4Do you also manufacture PEEK components?

Yes — PEEK is our preferred high-temperature plastic. We mill PEEK seals, insulators and implants with tolerances up to IT7.

Q5What do titanium milled parts cost?

Titanium is approx. 3–5× more expensive than aluminum in machining (material + tool costs). Simple titanium parts from approx. €100–200/piece, complex 5-axis parts from approx. €300–800.

Q6Do you procure the raw material?

Yes — we procure all special materials through our network. Titanium plates, brass round bars, copper blocks and PEEK semi-finished products available at short notice.

Q7Can you mill copper heat sinks?

Yes — E-Cu57 heat sinks with fine fin structures. Copper requires sharp tools and adapted cutting data to minimize burr formation.

Q8Which surface treatments do you offer?

Brass: Nickel plating, gold plating, polishing. Titanium: Anodizing (Type II/III). Copper: Nickel plating, tin plating. PEEK/POM: Generally no post-treatment required.

Request Special Material Milled Part

Send us your drawing or STEP file — we provide a binding quotation within 24 hours for your milled part from brass, titanium, copper or plastic.