Milled Parts from Stainless Steel & Steel

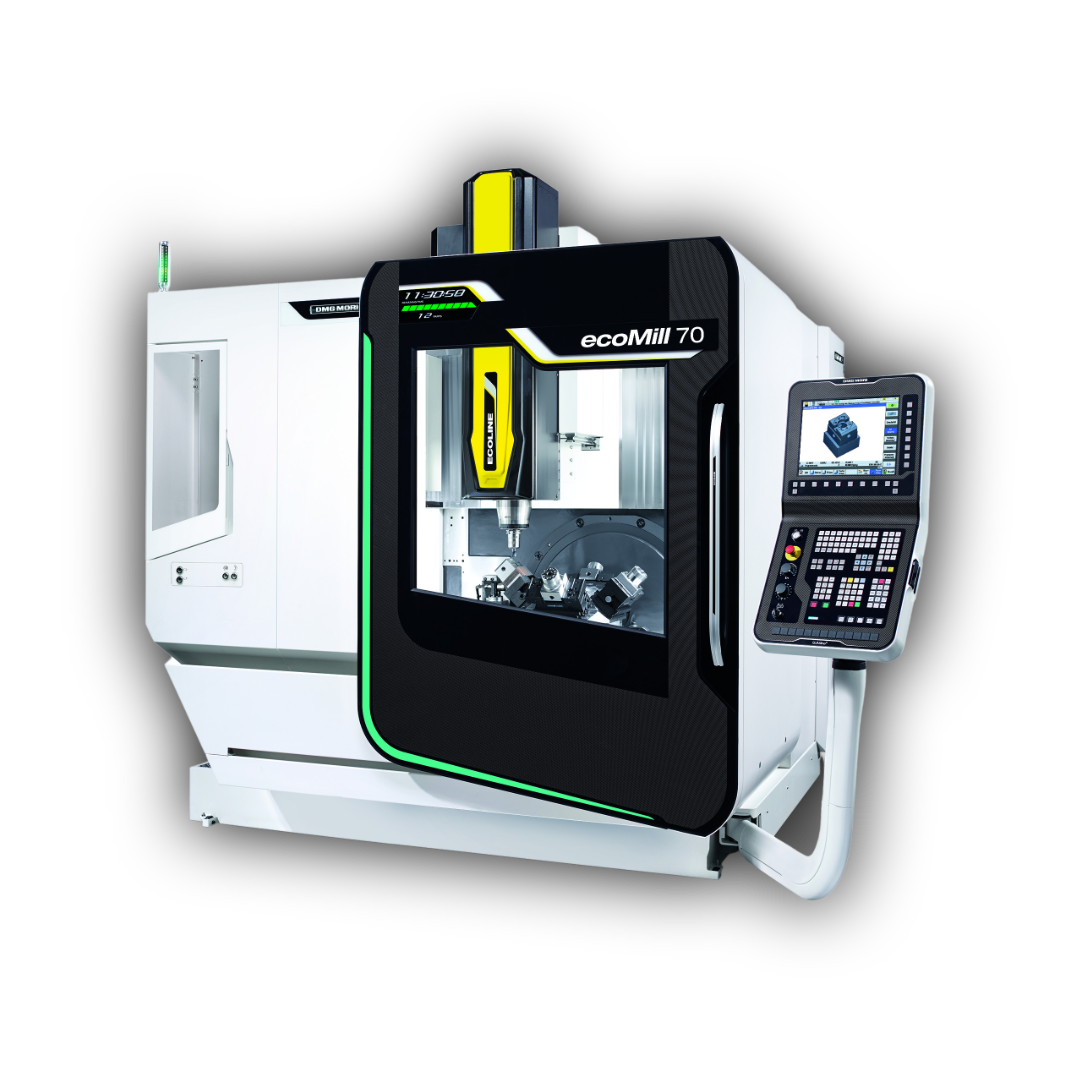

CNC milled parts from V4A, V2A, 42CrMo4 and tool steel. 5-axis machining on DMG Mori Ecomill 70. Single parts to small series — quote in 24h.

CNC Milling Stainless Steel & Steel

Stainless steel and steel place high demands on machining: Low cutting speeds, high cutting forces and heat generation require stable machines, optimal tool selection and well-designed cooling strategies. Our 5-axis machining enables complex geometries in a single setup.

On our DMG Mori Ecomill 70 (travel 700 × 560 × 510 mm) we manufacture milled parts from all common stainless steel and steel grades. The 5-axis capability allows undercuts, angled bores and freeform surfaces without re-clamping.

Stainless Steel & Steel Grades for Milled Parts

From corrosion-resistant V4A to high-strength tool steel — we mill the right material for your application.

1.4404 / V4A (AISI 316L)

Molybdenum-bearing stainless steel with enhanced corrosion resistance. For chemical, pharmaceutical, food and medical applications.

1.4301 / V2A (AISI 304)

The standard stainless steel: Good corrosion resistance, good weldability. For general applications and mechanical engineering.

42CrMo4 (1.7225)

Quenched and tempered steel with high strength (1,100 MPa). For highly stressed machine parts, gears and shafts.

S355J2 (1.0577)

Structural steel with good weldability (355 MPa). Economical for brackets, consoles and fixtures.

C45E (1.1191)

Case hardening and quenched/tempered steel for shafts, axles and mechanically stressed parts. Good machinability.

1.2379 (X155CrVMo12-1)

Cold work / tool steel with very high wear resistance (62 HRC). For stamping and cutting tools.

Benefits of Our Steel Milling Capability

5-Axis Machining

Complex geometries, undercuts and angled bores in a single setup. Fewer re-clampings = higher precision.

Corrosion Resistance

V4A milled parts for chemical, pharmaceutical and food industries. Passivation and electropolishing available as post-treatment.

High Strength

Quenched and tempered steels like 42CrMo4 (up to 1,100 MPa) for highly stressed components. Heat treatment before or after milling.

Small Series & Single Parts

Economical production from 1 piece. Optimized NC programs reduce unit costs even for small batch sizes.

Drawing or 3D Model

STEP, DXF, PDF — we process all common formats. CAM programming directly from your 3D model.

Surface Treatment

Burnishing, zinc plating, nickel plating, passivation or electropolishing — through certified partners.

Your Milled Part in 5 Steps

Send Inquiry

Send drawing or 3D model with material, quantity and delivery date. Material consultation also available.

Review & Quote

Feasibility check, clamping concept and material consultation. Binding quote within 24h.

Approval

After approval we procure raw material — plates, blocks or profiles in the desired grade.

CNC Milling

5-axis machining on DMG Mori Ecomill 70. Internal coolant, adapted cutting data and 100% inspection.

Delivery

Quality inspected, deburred, with surface treatment if needed. Carefully packaged and shipped.

Precision for Steel Milled Parts

Dimensional Tolerances from IT7

Fits H7/g6 also for hardened steels. IT6 with grinding or rework possible.

Surfaces to Ra 0.8

Stainless steel and steel typically deliver Ra 0.8–1.6 after milling. Ra 0.4 achievable with finishing cuts.

Flatness & Parallelism

Through thermally stable machining and stress relief annealing we minimize distortion for large milled parts.

Threads & Precision Bores

Metric threads, Helicoil inserts (recommended for stainless steel) and precision bores H7 in all steel grades.

Our Milling Machine for Stainless Steel & Steel

DMG Mori Ecomill 70

5-axis machining center with large work envelope. Travel 700 × 560 × 510 mm — stable enough for stainless steel and tool steel.

Steel Milled Parts for Your Industry

Mechanical Engineering

Housings, brackets, base plates from S355 and 42CrMo4 for plant and special machinery.

Chemical & Pharma

V4A milled parts for reactors, valves and plants. Electropolished and FDA-compliant on request.

Food Technology

Corrosion-resistant parts from V2A/V4A for processing machines. Passivated and hygiene-compliant.

Tool & Mold Making

Tool steel 1.2379 for stamping, cutting and forming tools. Hardened and ground on request.

Energy Technology

Highly stressed components from quenched and tempered steel for generators, turbines and hydraulic systems.

Automotive

Prototypes and special parts from steel and stainless steel. Single parts to small series.

Questions about Milled Parts from Stainless Steel & Steel

Q1Which stainless steel grades do you mill?

V4A (1.4404), V2A (1.4301), Duplex (1.4462) and more on request. Also austenitic and ferritic grades.

Q2Can you mill hardened steel?

Up to approx. 50 HRC we can machine with solid carbide cutters. For tool steel 1.2379 we recommend: Pre-mill → Harden → Grind functional surfaces.

Q3What is the difference between V2A and V4A?

V2A (1.4301) is the standard stainless steel. V4A (1.4404) additionally contains molybdenum and is significantly more resistant against chlorides and pitting. For chemical and food applications we recommend V4A.

Q4Do you offer heat treatment?

Yes — through certified partners we offer quenching and tempering, case hardening, nitriding and induction hardening. Heat treatment is included in the quotation.

Q5How large can steel milled parts be?

Up to 700 × 560 × 510 mm on our Ecomill 70. For larger parts we use our partner network.

Q6What do stainless steel milled parts cost?

Stainless steel is more expensive to machine than aluminum (lower cutting speeds, higher tool wear). Simple V2A parts from approx. €50–100/piece, complex V4A parts from approx. €150–400.

Q7Can you produce 5-axis milled parts?

Yes — our Ecomill 70 is 5-axis capable. This allows us to manufacture complex geometries with undercuts and angled bores in a single setup.

Q8Do you also manufacture welded assemblies?

Yes — milled individual parts can be TIG-welded into assemblies through our partners. We offer complete assemblies especially for V2A and S355.

Request Steel Milled Part

Send us your drawing or STEP file — we provide a binding quotation within 24 hours for your stainless steel or steel milled part.