Prototypes & Single Parts — First Samples to Pre-Series

CNC prototypes and single parts from metal from 1 piece. Turning and milling without tooling costs — from drawing to first sample in 5–8 working days.

From 3D Model to Finished Part

Prototypes and single parts must be available quickly — without tooling costs, without minimum quantities. CNC manufacturing makes this possible: your drawing goes directly into the CAM system, and we produce your part from batch size 1.

Whether turned on the NLX 2000 or milled on the Ecomill 70 — we manufacture prototypes, first samples, test parts and pre-series from all common metals. With the same precision as in series production.

Materials for Prototypes

Prototypes from series material — so your tests take place under real conditions.

Aluminium (6082/7075)

Lightweight, excellent machinability and readily available. The most common prototype material for lightweight and housing parts.

Stainless Steel (1.4301/1.4404)

For prototypes with corrosion requirements. Medical technology, food industry and offshore.

Structural Steel (S235/S355)

Robust and economical. For functional prototypes and mechanically stressed single parts.

Quenched & Tempered (42CrMo4)

High strength for stressed prototypes. Shafts, bolts and axles for load testing.

Brass & Copper

For prototypes with electrical or thermal requirements. Fittings and contact parts.

Titanium (Grade 2/5)

For prototypes in medical technology and aerospace. Lightweight, biocompatible and high strength.

Benefits for Prototypes & Single Parts

From 1 Piece

No minimum quantity, no tooling costs. Your prototype is machined directly from solid material.

No Tooling Costs

Unlike casting or injection moulding: CNC needs no mould tooling. The drawing is enough.

5–8 Working Days

From order receipt to ready-to-ship part. Express delivery in 3 working days available.

Series-Identical Quality

Prototypes with the same tolerances and surfaces as later in series production. Real functional testing possible.

All Common Formats

STEP, IGES, DXF, PDF — we process all common CAD formats. Material consultation included.

Seamless to Series

Your prototype is manufactured on the same machines as the later series. Transition without adjustments.

Your Prototype in 5 Steps

Send Drawing

3D model or 2D drawing with material, tolerances and quantity by email or upload.

Quote in 24h

Feasibility check and binding quote with unit price and delivery date — usually same day.

Approve

After your approval we start programming and procure raw material.

CNC Manufacturing

Turning on NLX 2000 and/or milling on Ecomill 70. 100% quality inspection.

Shipping

Carefully packaged with measurement protocol. Delivery within 5–8 working days.

Prototype Quality at Series Level

Tolerances IT7–IT8

Prototypes with series tolerances. IT7 as standard, IT6 on request. Ensuring real functional testing.

Surfaces Ra 0.8–1.6

Standard surfaces Ra 1.6, fine machining Ra 0.8. Polishing, anodizing or other coatings on request.

Measurement Protocol

Every prototype is 100% measured. Documentation of all critical dimensions with actual values.

Material Certificate

On request with mill certificate 3.1 per EN 10204. Traceability for regulated industries.

Machines for Prototypes

DMG Mori NLX 2000

CNC lathe for rotationally symmetric prototypes with complete machining.

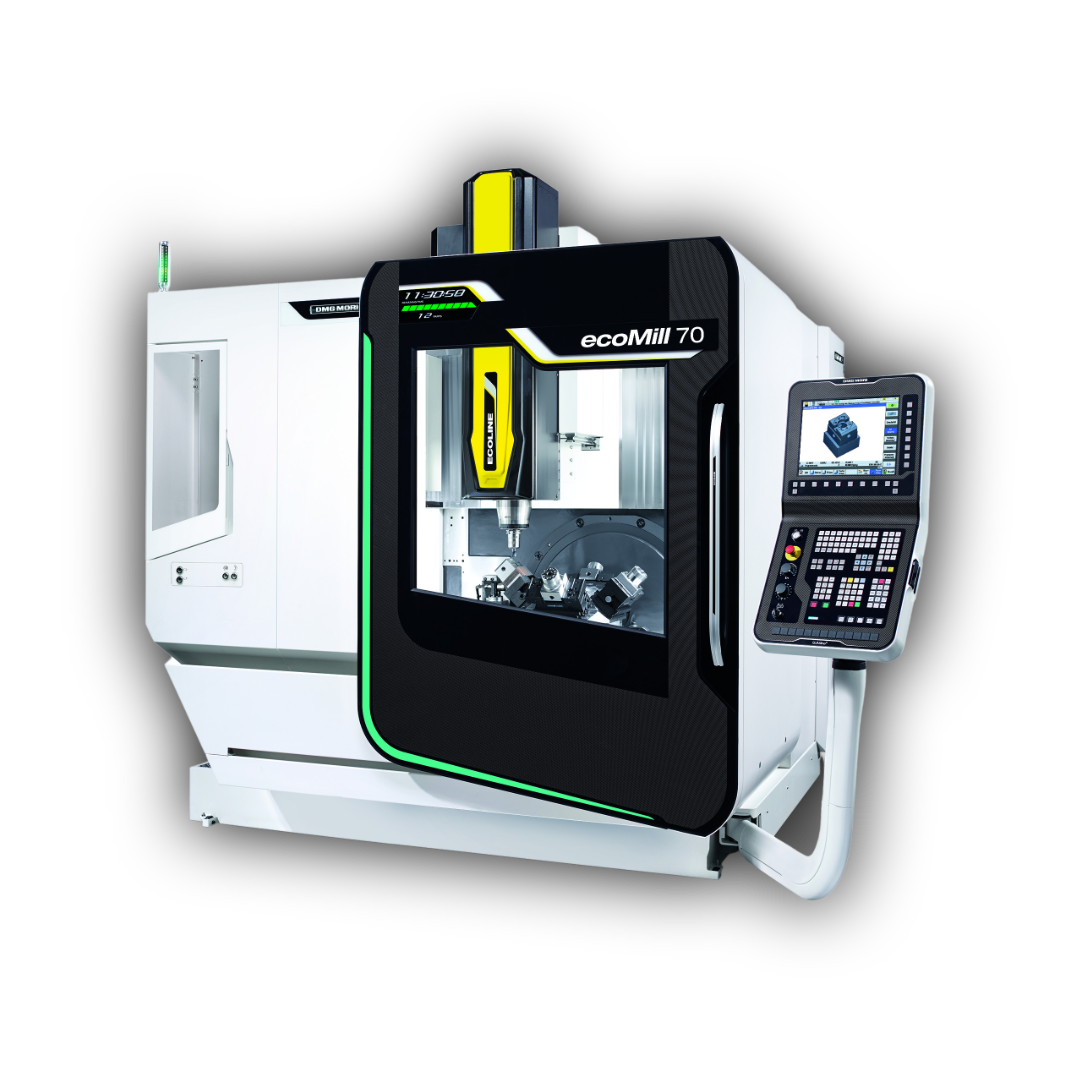

DMG Mori Ecomill 70

5-axis machining center for complex milled prototypes with demanding geometries.

Prototypes for Your Industry

Mechanical Engineering

Functional prototypes for load testing, test carriers and pre-series components.

Medical Technology

Prototypes from titanium and stainless steel for approval tests and clinical studies.

Research & Development

Test parts and specimens for lab tests, material trials and feasibility studies.

Startup & Product Dev.

From concept to tangible prototype. Iterate and optimize without tooling costs.

Special Machinery

Individual single parts for special constructions. Economical from 1 piece.

Maintenance & Spares

Discontinued spare parts reproduced from drawings or samples.

Questions about Prototypes & Single Parts

Q1What is your minimum order quantity?

From 1 piece. There is no minimum quantity and no tooling cost. This is the great advantage of CNC manufacturing over casting or injection moulding.

Q2What does a prototype cost?

Simple turned parts from approx. €30–60/piece, milled parts from approx. €80–150/piece. Price depends on material, geometry and tolerances. Quote in 24h.

Q3How long does manufacturing take?

5–8 working days from order confirmation (standard delivery). Express in 3 working days at surcharge available.

Q4What file formats do you accept?

STEP (.stp), IGES (.igs), DXF and PDF drawings. Even sketches with dimensions and tolerance specifications are sufficient for a quote.

Q5Do prototypes have the same quality as series parts?

Yes — prototypes are manufactured on the same machines with the same tolerances. Functional testing and material testing are identical.

Q6Can you also manufacture a pre-series?

Yes — pre-series of 5 to 50 pieces. Ideal for testing assembly processes and approval before series production.

Q7Do you also advise on material selection?

Yes — we advise on material selection considering strength, corrosion resistance, weight and cost.

Q8Can you manufacture single parts from a sample?

Yes — send us a sample part, we measure it and manufacture your single part or spare part accordingly. Even without existing drawings.

Request Prototype

Send us your drawing or 3D model — we deliver a quote within 24 hours. From 1 piece.