Aluminum Milled Parts from Drawing

CNC milled parts from aluminum from your drawing or 3D model. EN AW-6082, 7075, 5083 from single parts to small series. Quote within 24 hours.

Why Aluminum Milled Parts from CNC Manufacturing?

Aluminum is the ideal material for CNC milled parts: Low weight (2.7 g/cm³), excellent machinability and high cutting speeds enable economical production even with complex geometries. From simple plates with holes to 3D freeform parts — aluminum mills excellently.

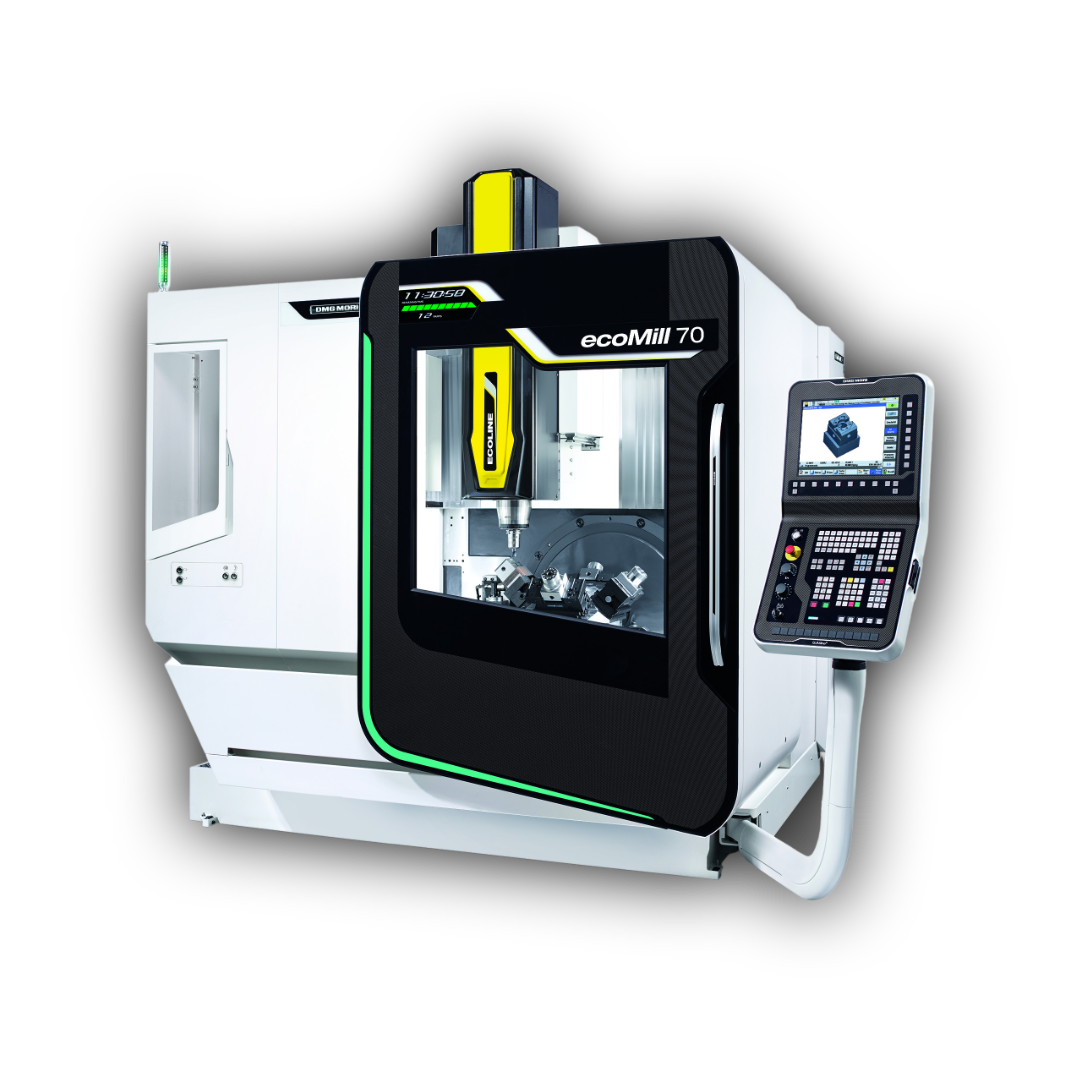

On our DMG Mori Ecomill 70 (travel 700 × 560 × 510 mm) we manufacture aluminum milled parts from STEP files, DXF drawings or PDF. Turn-mill parts with milling operations on the NLX 2000 are also possible.

Aluminum Alloys for Milled Parts

We mill all common aluminum alloys. The choice depends on strength, corrosion resistance and weldability.

EN AW-6082 T6 (AlMgSi1)

The standard structural alloy: Good strength (310 MPa), excellent anodizability and weldability. For general mechanical engineering.

EN AW-7075 T6 (AlZnMgCu)

The high-strength alloy (570 MPa). For aerospace, motorsport and structural components. Limited weldability.

EN AW-5083 H111 (AlMg4.5Mn)

Seawater resistant and good weldability. For shipbuilding, offshore and corrosion-stressed components. Medium strength.

EN AW-2024 T3 (AlCuMg1)

High strength (470 MPa) and good fatigue resistance. Classic aerospace aluminum. Not weldable, not anodizable.

EN AW-6060 T6 (AlMgSi)

Profile alloy with good surface finish. Excellently anodizable, ideal for housings and covers with decorative requirements.

EN AW-6061 T6 (AlMg1SiCu)

Versatile alloy with good strength (310 MPa) and corrosion resistance. Good weldability, widely used in the US market.

Benefits of Aluminum Milled Parts

3× Faster than Steel

Aluminum allows cutting speeds up to 3,000 m/min and high feed rates. This means shorter cycle times and lower unit costs.

Lightweight

At 2.7 g/cm³ only one third the weight of steel. Weight reduction up to 65% for structural components possible.

Excellent Anodizability

Anodizing in various colors possible (6082, 6060). Hard protection against wear and corrosion with decorative appearance.

Complex 3D Geometries

Pockets, freeform surfaces, thin walls — aluminum can be milled cleanly and with minimal distortion even for complex parts.

STEP, DXF & PDF

We work with all common data formats. STEP files are imported directly into CAM — quote often on the same day.

Good Weldability

5000 and 6000 series alloys are well TIG/MIG weldable. Assemblies can be joined after milling.

Your Milled Part in 5 Steps

Send Inquiry

Send drawing or 3D model (STEP, DXF, PDF) with desired alloy, quantity and delivery date.

Review & Quote

CAM feasibility, clamping concept and alloy consultation. Quote with unit price within 24h.

Approval

You approve the quote — we procure the raw material (plates, blocks or profiles).

CNC Milling

Manufacturing on DMG Mori Ecomill 70 (3-axis) or with live tools on the NLX 2000. 100% inspection.

Delivery

Quality inspected, deburred and carefully packaged. Surface treatment (anodizing) on request before delivery.

Precision for Aluminum Milled Parts

Dimensional Tolerances from IT7

Fits H7/g6 also for deep pockets and long bores. IT6 with rework possible.

Surfaces to Ra 0.4

Aluminum delivers very good surfaces directly from the mill. Polishing or anodizing for Ra < 0.2 µm possible.

Flatness ≤ 0.05 mm

Through adapted clamping and machining strategies we minimize distortion even for large-area parts.

Threads & Precision Bores

Metric threads, Helicoil inserts and precision bores H7 in all aluminum alloys.

Our Machines for Aluminum Milling

DMG Mori Ecomill 70

3-axis machining center with large work envelope. Travel 700 × 560 × 510 mm — ideal for aluminum plates and blocks.

DMG MORI NLX 2000

Universal lathe with live tooling. For turn-mill parts and rotationally symmetric milling tasks.

Aluminum Milled Parts for Your Industry

Mechanical Engineering

Adapter plates, brackets and housings from 6082 for plants and special machinery.

Aerospace

Structural components from 7075 and 2024 with tight tolerances and material certificate.

Medical Technology

Housings and functional parts from anodized 6082/6060 for medical devices.

Electronics & Enclosures

Heat sinks, front panels and electronic enclosures from 6060/6082 with anodized finish.

Motorsport

Lightweight high-performance parts from 7075-T6 — brackets, adapters, struts.

Prototyping

Fast realization of 3D models into functional prototypes. Changes implementable at short notice.

Questions about Aluminum Milled Parts

Q1Which aluminum alloys do you mill?

All common EN AW alloys: 6082, 7075, 5083, 2024, 6060, 6061 and more. Also extruded profiles and cast alloys on request.

Q2Can you mill from a STEP file?

Yes — STEP files are imported directly into our CAM system. We also process IGES, DXF, DWG and PDF drawings. For 3D models, we often provide the quote on the same day.

Q3How large can aluminum milled parts be?

On our Ecomill 70 we process parts up to 700 × 560 × 510 mm. Larger parts on request — possibly through cooperation partners.

Q4Do you offer anodizing?

Yes — through certified partners we offer anodizing (natural, black, colored) and hard anodizing. The 6000 series alloys are particularly well suited for this.

Q5What do aluminum milled parts cost?

Aluminum is economical to mill thanks to high cutting speeds. Simple parts from approx. €20–50/piece (single part), complex 3D parts from approx. €80–200. In small series, unit costs decrease significantly.

Q6Can you mill thin walls?

Yes — through adapted cutting strategies (HSC milling, small step-over) and special tools, we manufacture wall thicknesses down to 0.5 mm without distortion.

Q7What is the difference between 6082 and 7075?

6082 is the all-rounder: Good weldability, anodizable, moderate strength (310 MPa). 7075 is the high-performance alloy (570 MPa), but not weldable and limited anodizability. 7075 for highly stressed parts, 6082 for everything else.

Q8What is the minimum order quantity?

From 1 piece — single parts and prototypes as well as small series (100+). For series, optimized NC programs reduce unit costs.

Request Aluminum Milled Part

Send us your drawing or STEP file — we provide a binding quotation within 24 hours.